Autonomous

Logistics, Now.

Watch Full Video

Fleet autonomous logistics

24/7. On-time. Safe.

Factories · Yards · Ports

8 years of successful deployments and real-world autonomous logistics delivering major cost savings.

Solutions

Seoul Robotics' solution surpasses the limitations of conventional autonomous driving technologies, leading the market with a fully commercialized and proven system.

ATI

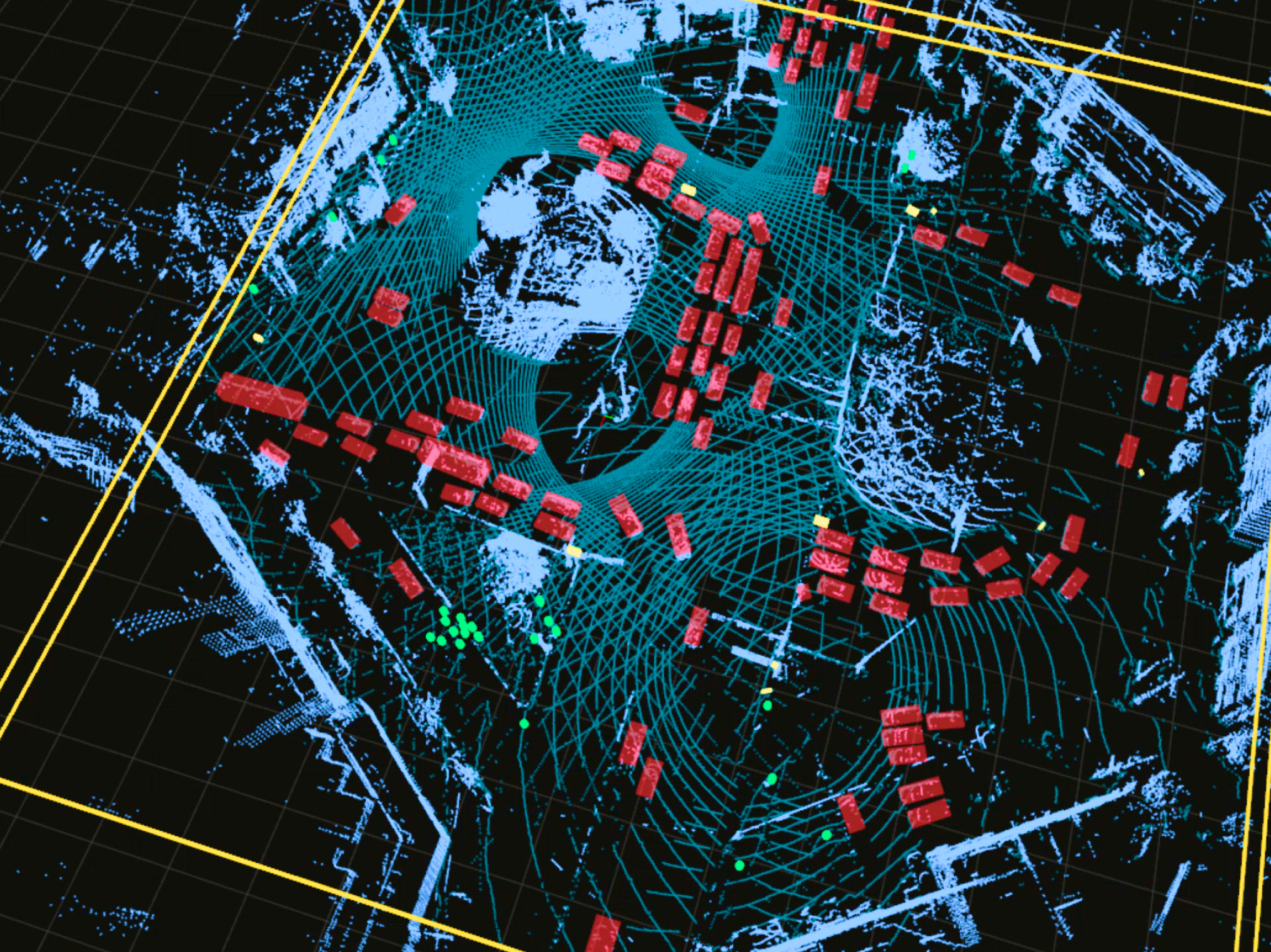

Autonomy Through Infrastructure

Seoul Robotics' Autonomy Through Infrastructure (ATI) platform enables full-scale, fleet-level autonomous driving by automating the entire vehicle movement process within automotive factories and large-scale logistics hubs. It is the world's first globally infrastructure-based autonomy platform, fully validated and ready for immediate commercial deployment.

AYT

Autonomous Yard Tractor

Seoul Robotics' Autonomous Yard Tractor (AYT) solution brings autonomy to yard tractors operating within ports. Engineered for precise and adaptive performance, it ensures safe and efficient operation in complex environments where vehicles, pedestrians, and equipment interact. The system performs flawlessly day or night, in all weather conditions.

ATS

Advanced Technology Solutions

Seoul Robotics' Advanced Technology Solutions (ATS) leverage LiDAR, cameras, and machine learning to detect vehicles, trains, and pedestrians, analyze traffic events, and deliver both real-time and historical data.

Differences

Seoul Robotics sets a new standard for autonomous driving, backed by proven technology and a distinct competitive edge.

Explore Our TechnologyOrchestration

Performance

Orchestration

Trusted by

Global Leaders

Our solutions are validated and trusted by industry leaders worldwide,

deployed across top-tier automotive manufacturers and logistics companies.